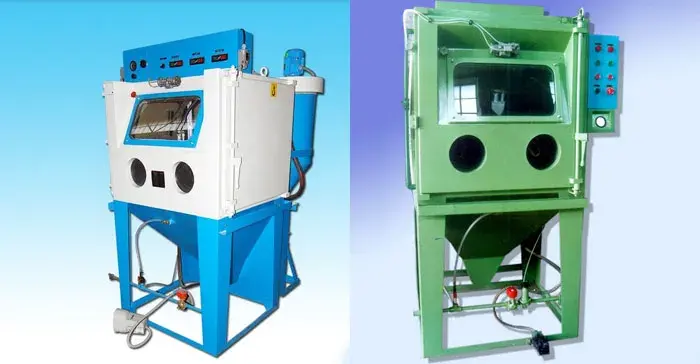

AeroWheel Surface Finishing: Your Jodhpur Source for Advanced Wet Blast Cabinets

When you need an efficient, versatile surface finishing solution, look to AeroWheel Surface Finishing. We specialize in designing and manufacturing high-quality wet blast cabinets that deliver exceptional results in various Jodhpur-based industries.

Understanding Wet Blast Cabinets

Wet blast cabinets, also known as slurry pump or vapor blasting cabinets, combine the cleaning power of abrasive blasting with the benefits of water. A slurry of water and fine abrasive is blasted onto the workpiece, resulting in these key advantages:

- Dust Suppression: Eliminating the health and visibility hazards of traditional dry blasting.

- Finer Finishes: Achieves a smooth, uniform surface on even delicate components.

- Reduced Abrasive Embedment: The water minimizes the risk of abrasive particles becoming lodged in the material.

- Environmentally Friendly: Recycled media and water reduce waste.

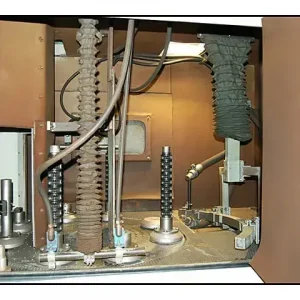

How AeroWheel Wet Blast Cabinets Work

- Slurry Preparation: Fine abrasive media is mixed with water in the cabinet’s hopper.

- Pumping: A durable slurry pump draws the mixture from the hopper to the blast gun.

- Compressed Air Injection: Compressed air atomizes the slurry, propelling it at high speed for surface treatment.

- Recirculation: Slurry is collected, filtered, and returned to the hopper for cost-effective operation.

Wet Blast Cabinet Applications in Jodhpur

- Delicate Deburring: Removes burrs without damaging fragile parts or edges.

- Surface Preparation: Creates an ideal surface for coatings, plating, or further operations.

- Decorative Glass Etching: Produces custom designs with a refined, frosted finish.

- Cleaning Plastic Molds: Safely removes residues without harming delicate mold surfaces.

Why Choose AeroWheel for Wet Blasting in Jodhpur

- Exceptional Quality: Our cabinets are built with durability and precision in mind.

- Customization: We design machines to address your exact Jodhpur production flow and materials requirements.

- Local Expertise: AeroWheel understands the nuances of manufacturing in Jodhpur.

- Comprehensive Support: Guidance every step of the way, plus after-sales parts and service.

- Value-focused: Experience advanced performance at a competitive price point.

Features of AeroWheel Wet Blast Cabinets

- Large viewing window with wiper/washer for safe operation.

- User-friendly, ergonomic design with a single footswitch control.

- Quick-release pump for streamlined maintenance.

- Available in pressure or suction configurations.

Let AeroWheel Elevate Your Surface Preparation

If you’re seeking a dust-free, precise, and adaptable surface finishing solution in Jodhpur, wet blasting cabinets is an excellent choice. Consult with AeroWheel Surface Finishing to explore how a custom-built wet blast cabinet can empower your operations. Browse case studies on our projects page, get a quote, and unlock new levels of efficiency and quality.

Reviews

There are no reviews yet.