AeroWheel Surface Finishing: Your Suction/Vacuum Blast Cabinet Experts in Jodhpur

AeroWheel Surface Finishing combines advanced technology and a commitment to safety to deliver exceptional suction blast cabinets for Jodhpur businesses. Achieve your desired surface finishes cost-effectively, with machines ideally suited for diverse applications.

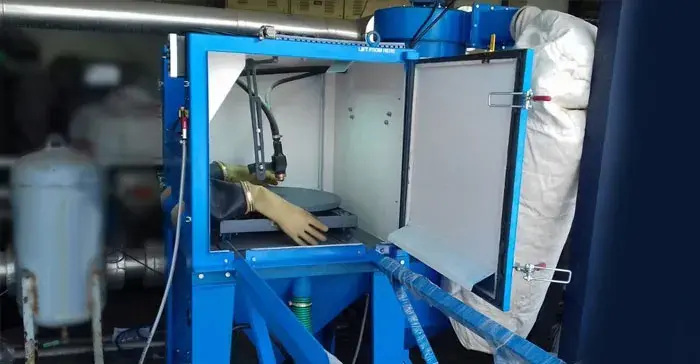

Understanding Suction/Vacuum Blast Cabinets

These cabinets use induction-suction blasting principles, drawing light-weight abrasives into the airflow for cleaning light corrosion and imparting fine matte finishes. Our cabinets incorporate:

- Reclaimers: Ensuring consistent finishing by separating dust and debris from reusable abrasive.

- Dust Collectors: Maintaining a clean and safe working environment.

When to Choose AeroWheel’s Suction Blast Cabinets

- Heat Treatment Shops: Prepare components with ease.

- Tool & Die Makers: Achieve precision surface preparation.

- Light Metal Shot Peening: Strengthen components effectively.

- Smaller-Scale Operations: Enjoy budget-friendly, efficient blasting solutions.

Advantages of Suction Blasting Technology

- Versatility: Clean, smooth, and finish various materials and component shapes.

- Enhanced Control: Ideal for delicate work and light abrasive media.

- Continuous Operation: Built-in reclaimers eliminate frequent refilling.

- Affordability: Cost-effective investment with lower compressed air needs.

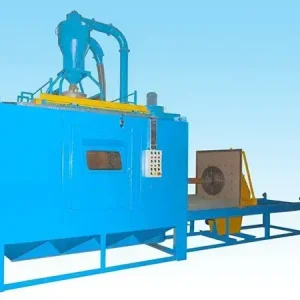

Features of AeroWheel Suction Blast Cabinets

- Quality Manufacturing: Built to last, ensuring trouble-free performance.

- Easy Maintenance: Simplified design for smooth upkeep.

- Safety Focused: Prioritizing clean working conditions.

- Customization: Options to tailor the cabinet to your specific needs.

AeroWheel: Your Jodhpur Solution

We understand the need for reliable, high-performing suction/vacuum blast cabinets in Jodhpur industries. That’s why we combine high-quality components with our commitment to your success.

Get in Touch for the Perfect Cabinet

Let’s discuss your surface finishing needs! Contact AeroWheel Surface Finishing today to explore our suction blast cabinet options in Jodhpur and receive a personalized quote.

Reviews

There are no reviews yet.