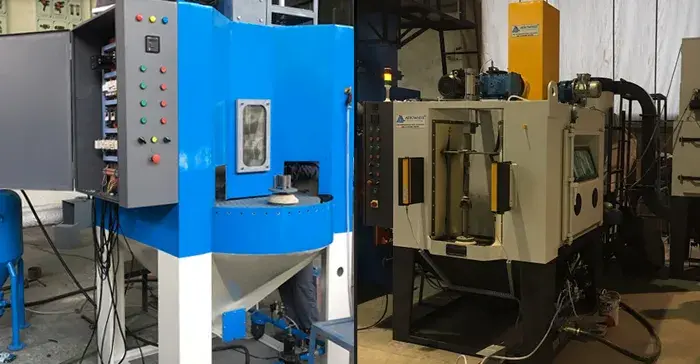

AeroWheel Surface Finishing: Your Jodhpur Source for Rotary Indexing Machines

AeroWheel Surface Finishing excels in manufacturing custom rotary indexing machines, empowering businesses in Jodhpur to achieve optimal surface finishing results. These machines are particularly well-suited for blasting complex, fragile, or varying-sized components.

What is a Rotary Indexing Machine?

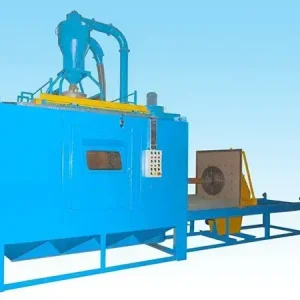

Rotary indexing machines (also known as rotary table shot blasting machines) employ a rotating table system to ensure uniform abrasive blasting coverage on a variety of workpiece shapes and sizes. They are incredibly versatile for industries and applications where precision is key.

Why Choose AeroWheel Surface Finishing for Rotary Indexing Machines in Jodhpur

- Superior Results: Achieve the precise surface finish you need for castings, forgings, heat-treated parts, and more.

- Customization: Get machines tailored to your exact workpiece specifications and production flow.

- Local Expertise: Benefit from our Jodhpur-based team’s knowledge of your unique blasting needs.

- High-Quality Construction: Enjoy years of durable performance with our robust machines.

- Commitment to Your Success: We go above and beyond to ensure your satisfaction.

Understanding the Rotary Indexing Process

AeroWheel’s machines typically operate on a suction blasting principle. Here’s the basics:

- Loading: Components are placed on the rotary indexing table outside the enclosed blasting chamber.

- Indexing: The table rotates, moving components sequentially into the blasting area.

- Precision Blasting: Efficient blasting takes place within the chamber as the table keeps rotating.

- Continuous Production: While one workpiece is blasted, others are loaded/unloaded to streamline the process.

Features & Benefits of Our Machines

- Single or dual table designs

- High load capacity

- Ideal for descaling, deburring, deflashing, and various surface preparations

- Handles delicate and oddly shaped components

- Customizable features available

Get Your Custom Solution – Contact AeroWheel Today!

Tell us about your surface finishing challenges in Jodhpur! We’ll design a rotary indexing machine to solve them. Browse our projects and request a quote to get started.

Reviews

There are no reviews yet.