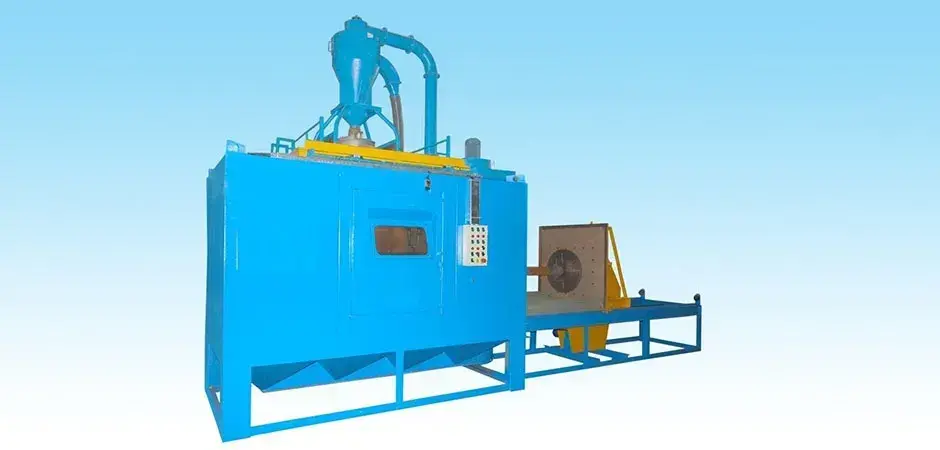

Jodhpur’s Premier Manufacturer of Roll Etching Machines

If you’re seeking exceptional roll etching machines to optimize your rolling mill processes, look no further than our Jodhpur-based manufacturing facility. We specialize in delivering high-performance equipment designed to elevate your surface finishing capabilities.

What is a Roll Etching Machine?

Roll etching machines utilize abrasive blasting technology to precisely control the surface texture of rolls used in rolling mills. This controlled etching significantly impacts the final product quality in industries like steel, aluminum, textile, and paper production.

Benefits of Our Jodhpur-Made Roll Etching Machines

- Precision Etching: Achieve the exact surface roughness (Ra value) your rolling operations demand.

- Enhanced Efficiency: Streamline your roll preparation process with automated, easy-to-use machines.

- Customization: We tailor machine size, features, and automation to suit your unique setup.

- Durability: Enjoy years of reliable service thanks to robust construction and quality components.

- Unmatched Expertise: Benefit from our deep knowledge of roll etching and commitment to client success.

How Roll Etching Machines Work

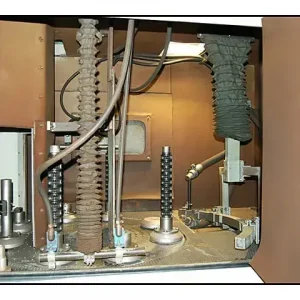

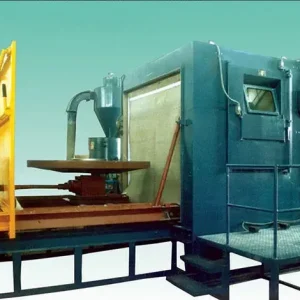

- Roll Loading: Rolls are securely mounted on a motorized work car within the enclosed blasting chamber.

- Abrasive Blasting: High-pressure air propels abrasive media onto the rotating roll, creating the desired etch.

- Automatic Reciprocation: Nozzles move horizontally in sync with the roll, ensuring uniform surface treatment.

- Media Recycling: Efficient systems reclaim and recirculate reusable abrasive media.

- Dust Control: Powerful dust collectors maintain a clean, safe working environment.

Key Features of Our Roll Etching Machines

- Mechanical gun reciprocation for consistent blasting

- Automatic roll rotation for even finishing

- Vibratory sieve classifier to maintain desired Ra values

- Roll drive and track for easy loading/unloading

- Superior dust collection

- Bright chamber illumination for safe, accurate work

Explore Our Turnkey Solutions – Contact Us Today!

Let us partner with you to create the perfect roll etching solution for your Jodhpur facility. Get in touch to discuss your requirements, receive a personalized quote, and see examples of our successful projects.

Reviews

There are no reviews yet.