AeroWheel Surface Finishing – Your Source for Premium Airless Shot Blasting in Jodhpur

AeroWheel stands as a trusted manufacturer and exporter of exceptional airless shot blasting machines. From Jodhpur to Dubai, Kuwait, and beyond, we’re recognized for delivering innovative, custom solutions that meet the needs of industries worldwide.

Understanding Airless Shot Blasting

In this process, high-speed centrifugal wheels propel abrasive media onto the workpiece, without using compressed air. This offers greater efficiency and controlled surface treatment for these key applications:

- Descaling & Rust Removal: Achieve a flawlessly clean substrate pre-coating or other processes.

- Deburring: Thorough deburring with exceptional consistency, even on complex geometries.

- Shot Peening: Improve fatigue strength and longevity of critical components.

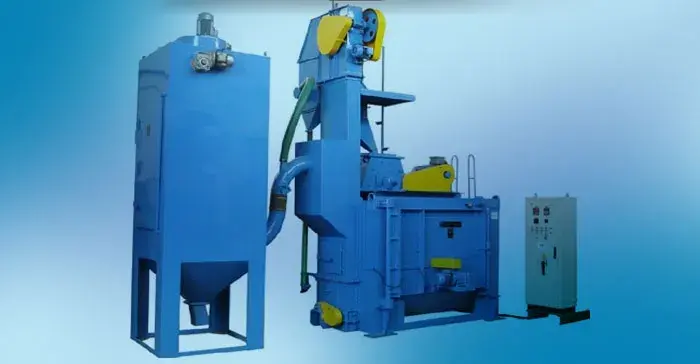

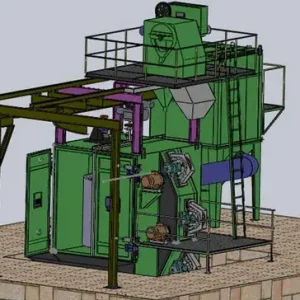

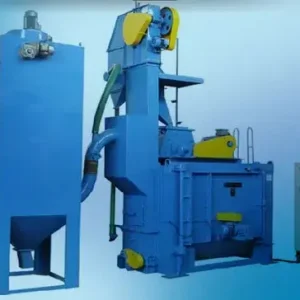

AeroWheel’s Airless Shot Blasting Machines

We bring versatility and expertise to your Jodhpur operations with a range of machine types:

- Hanger Shot Blasting Machine: Rotates workpieces for all-around coverage – ideal for intricate parts.

- Swing Table Shot Blasting Machine: Efficient blasting of parts mounted on a rotating table.

- Tunnel Type Shot Blasting Machine: High-throughput processing of long or flat workpieces on a conveyor.

- Tumble Blast Machine: Batch processing for smaller, mixed components.

Why Choose AeroWheel in Jodhpur

- Quality-Driven: Engineered for long-term reliability and consistent, superior results.

- Client-Focused: Flexible designs tailored to your production flow and materials.

- Global Reach: We deliver and support solutions in India and worldwide.

- Cost-Effective: Advanced surface finishing capabilities without excessive price tags.

Features Common to Our Shot Blasters

- Highly efficient blast wheels for optimized performance.

- Robust wear-resistant liners for machine protection.

- Advanced dust collection systems for a clean workplace.

- Customizable options to suit your exact Jodhpur operations.

Ready to Transform Your Surface Preparation?

Partner with AeroWheel Surface Finishing – the trusted choice for airless shot blasting innovation in Jodhpur. Browse our product pages for in-depth model details, view successful project examples, and request a personalized quote to discover how we can meet your challenges.

Sandeep Bishnoi –

Greetings, fellow craftsmen! I recently incorporated an Airless Shot Blasting Machine into my workshop here in Jodhpur, and let me share my exhilarating experience with you. This cutting-edge piece of equipment has truly revolutionized the way I approach surface preparation, and I couldn’t be more thrilled with the results.

Let’s dive right into the heart of the matter – the manufacturer. After extensive research, I decided to go for a reputable Airless Shot Blasting Machine manufacturer in India. The precision and attention to detail in the design and construction of this machine speak volumes about their commitment to quality. The fact that it’s manufactured in India adds an extra layer of confidence, knowing that it’s tailored to handle the unique challenges that Jodhpur’s industrial landscape presents.

Now, the performance – and boy, does it deliver! The airless shot blasting mechanism ensures a uniform and thorough surface treatment that’s essential for achieving impeccable results. Whether I’m working on metal components or preparing surfaces for coating, this machine handles it all with finesse. The versatility it brings to my workshop has significantly expanded the scope of projects I can undertake.

Living in Jodhpur, where the weather and environmental conditions can be quite demanding, durability is a prime concern. The robust build of this Airless Shot Blasting Machine stands up to the challenge. It’s clear that the manufacturers have considered the need for longevity, making it a solid investment for any serious craftsman.

One aspect that truly sets this machine apart is its efficiency. The process is quick, and the machine is designed to minimize abrasive consumption, saving both time and resources. The adjustable settings provide a level of control that allows me to tailor the blasting process to the specific requirements of each project, ensuring optimal results every time.

Cleanliness is next to godliness, especially in a bustling workshop. The integrated dust collector in this Airless Shot Blasting Machine keeps the workspace clean, contributing to a safer and healthier environment. It’s a thoughtful addition that adds to the overall appeal of the machine.

In conclusion, if you’re serious about precision and efficiency in your surface preparation endeavors, the Airless Shot Blasting Machine from a trusted Indian manufacturer is a game-changer. My workshop in Jodhpur has certainly benefitted, and I’m excited to see the incredible results it will continue to deliver in future projects. Here’s to raising the bar in surface treatment – cheers, fellow craftsmen!